Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

When it comes to the world of machinery and automotive engineering, there are countless components that work together to ensure smooth, efficient operation. One such critical yet often overlooked component is the gearbox oil seal. It might seem like a small part of the larger mechanical system, but without it, the performance and longevity of your gearbox could be severely compromised. In this blog, we'll take a closer look at what a gearbox oil seal is, why it’s so important, how it works, and most importantly, how to choose the right gearbox oil seal supplier for your needs.

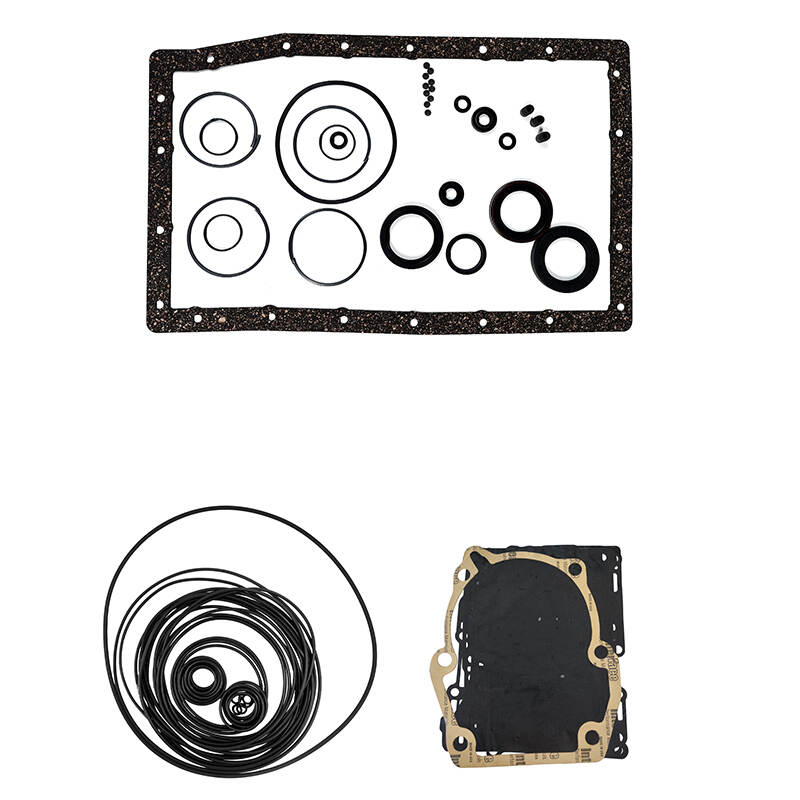

A gearbox oil seal is a crucial part of the gearbox, designed to prevent oil from leaking out and dirt, water, and other contaminants from entering. It’s typically made from rubber or synthetic materials that offer resistance to both heat and friction, ensuring that the gearbox remains sealed and operates efficiently over time.

The gearbox is one of the most important parts of any vehicle or machinery that uses a motor to transfer power. It’s responsible for converting the power from the engine into rotational movement that drives the wheels, propellers, or other moving parts. Gearboxes are subject to high stress, friction, and temperature changes, which is why the oil within them needs to be kept in place and free from contaminants. This is where the oil seal comes in.

While it may seem like a small and simple component, the gearbox oil seal plays a huge role in the overall performance and maintenance of the gearbox. Here are some key reasons why they are so vital:

Prevent Oil Leaks: The most obvious function of the gearbox oil seal is to prevent the lubricant inside the gearbox from leaking out. Oil leakage can lead to severe damage to the gears and other components, causing the gearbox to wear out more quickly. Without a properly functioning seal, the gearbox may lose its lubrication, which could result in the gears grinding, overheating, or seizing.

Protect Against Contaminants: Gearboxes are exposed to various contaminants, such as dust, dirt, water, and road salt. These can enter the gearbox and cause corrosion or sludge buildup, significantly reducing its lifespan. The oil seal ensures that the lubricant remains uncontaminated, allowing the gears to operate smoothly.

Maintain Optimal Pressure: Gearboxes need to maintain a certain internal pressure to function correctly. A damaged or worn-out oil seal can lead to pressure loss, which may cause the gearbox to malfunction, leading to costly repairs or even complete failure.

Improve Efficiency and Longevity: By preventing leaks and contamination, the oil seal helps the gearbox operate more efficiently. It ensures that the oil stays where it’s needed, reducing friction and wear on the gears. This results in better fuel efficiency and a longer service life for the gearbox.

A gearbox is typically sealed with oil to reduce friction between the moving parts. When these parts move, they generate heat and friction, which could wear down the metal components over time. The oil in the gearbox acts as a lubricant, reducing friction and dissipating heat. However, if oil were allowed to escape or contaminants were allowed to enter, the gearbox would not be able to perform efficiently.

The oil seal sits at the point where the rotating shaft exits the gearbox. It creates a tight barrier to keep the oil inside the gearbox and prevent any foreign materials from entering. Gearbox oil seals are often designed with a lip that presses tightly against the shaft. This design helps to keep oil from leaking while allowing the shaft to rotate freely without much resistance.

The materials used for the seal need to be durable and resistant to both heat and friction. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane. These materials can handle the high temperatures generated in the gearbox and the friction caused by the rotating parts, ensuring a tight seal over long periods.

Despite their durability, gearbox oil seals can wear out over time. Some common problems that might occur with gearbox oil seals include:

Cracking or Hardening: Over time, exposure to heat and friction can cause the rubber material in the seal to harden or crack, compromising its ability to form a tight seal.

Deformation: Heat, pressure, and vibration can cause the oil seal to lose its shape or deform, leading to leaks or ineffective sealing.

Contamination: If the seal is damaged, it might allow contaminants such as dirt, water, or debris to enter the gearbox, which can lead to damage to the gears and other internal components.

Incorrect Installation: Sometimes, the oil seal can be improperly installed during manufacturing or maintenance, leading to an inadequate seal and oil leakage.

Wear and Tear: As with any mechanical part, continuous use and friction can cause the oil seal to wear out over time, reducing its effectiveness.

When selecting a gearbox oil seal supplier, there are a few critical factors to consider. Whether you are maintaining a car, industrial machinery, or any other equipment with a gearbox, choosing the right supplier ensures you get high-quality seals that will keep your gearbox in optimal condition.

The first thing to consider when selecting a gearbox oil seal supplier is the quality of their products. High-quality seals are made from durable materials such as nitrile rubber, fluorocarbon, or polyurethane, which can withstand extreme temperatures and friction. Look for suppliers that provide seals designed for the specific type of gearbox you are working with, whether it's for an automotive transmission, heavy machinery, or industrial applications.

Gearbox oil seals come in various sizes and specifications depending on the gearbox type and application. A reputable gearbox oil seal supplier will offer a wide range of seals for different gearboxes, ensuring you can find the exact seal you need. They should also provide options for different materials and designs to suit the specific demands of your machinery.

One of the most important factors in choosing a supplier is their reputation. Look for suppliers with positive reviews from other customers in your industry. Online reviews, testimonials, and case studies can provide valuable insight into the quality of the supplier's products and customer service. A supplier with a good reputation will often be more reliable, providing seals that last longer and perform better.

A reliable gearbox oil seal supplier will have strong customer support. Whether you need help selecting the right seal for your gearbox or have questions about installation or maintenance, a knowledgeable support team can make a big difference. Check if the supplier offers technical support, assistance with troubleshooting, and guidance on product selection.

If you work with a variety of gearboxes or need specialized oil seals, it might be useful to find a supplier that offers customized seals tailored to your specific requirements. Some suppliers offer bulk discounts or custom manufacturing options for unique applications, which can be an advantage if you're working with specialized machinery or have high-volume needs.

Another important consideration is delivery time. Make sure the supplier can deliver the seals within a reasonable time frame to avoid downtime. Some suppliers offer express shipping or can accommodate urgent orders if necessary. It's also important to check if they have a reliable stock of seals so that you don’t have to worry about backorders.

In the world of machinery and automotive engineering, gearbox oil seals are often an unsung hero, working tirelessly to ensure that your gearbox remains efficient, free from leaks, and protected against contaminants. Choosing the right gearbox oil seal supplier is essential to ensuring that you get high-quality seals that will keep your machinery running smoothly for years to come. When selecting a supplier, consider factors such as product quality, range of options, customer service, and delivery times to make sure you’re getting the best possible seals for your needs.

With the right gearbox oil seal supplier by your side, you can rest assured that your gearboxes will stay lubricated, protected, and efficient, helping your machinery perform at its best and last longer.